As soon as possible we like to begin prototyping, and it’s important to understand all the different types of prototype we make, and why.

Very early in a project, when we’re trying to work out how something might work we will build proof of concept models. These are crude mechanisms and assemblies that we can use to see how something will function. We will usually combine modified ‘off the shelf’ parts with some simple printed or machined parts to see if a concept is feasible.

This is a continuous process, usually designing by day, and printing overnight. As the design improves we get more detail in and can optimize as we iterate. We’re now making works like models.

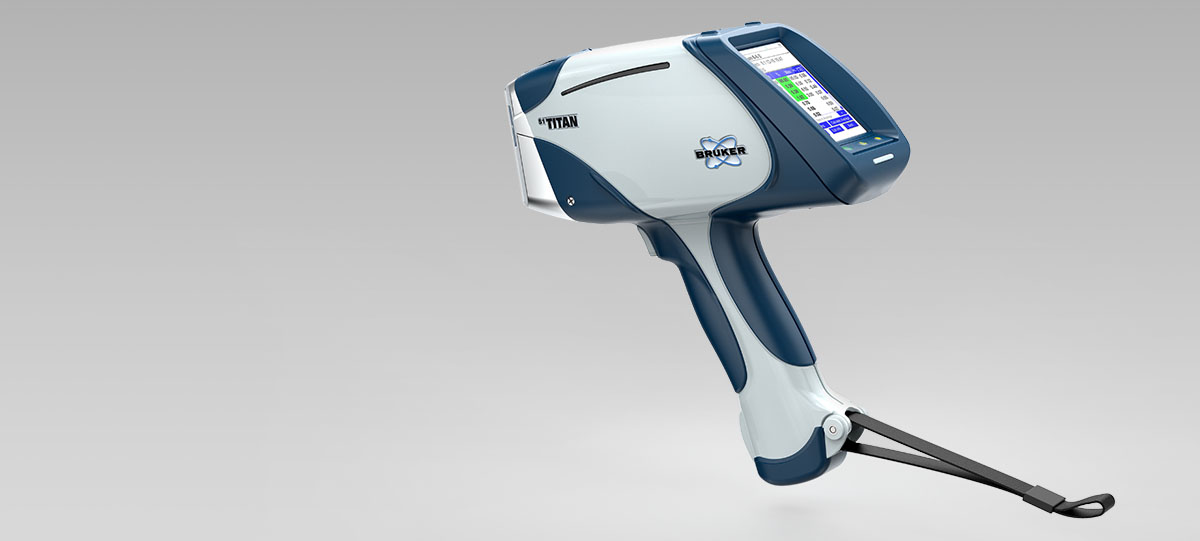

But we don’t just care about the function of something. Once everything performs functionally as expected we will then work out the enclosure for the design – how is it made, how is it assembled, how is it to hold and use – as these are all important functions too. We will make multiple looks like models as we go, and these are often shared with clients for further feedback. If we need to we will redesign mechanisms to get the best overall solution, that combines form and function.

“Working with Eclipse was an absolute pleasure from start to finish. Their team was incredibly responsive, always quick to address any questions or concerns we had. We were amazed by their creativity and ability to transform our vision into a beautifully executed design. ”

We have a case study available showing the process we used to update this medical cart…

The SpotOn Virtual Smart Fence is the first and only dog containment system that allows dog owners to keep track of their dogs wherever they go.