Thermo Electron engaged Eclipse to research and design a next-generation toxic vapor analyzer that would better align with evolving market needs and user expectations. The result was the TVA DataManager, a breakthrough device that redefined industry standards for performance, comfort, and safety in field detection tools.

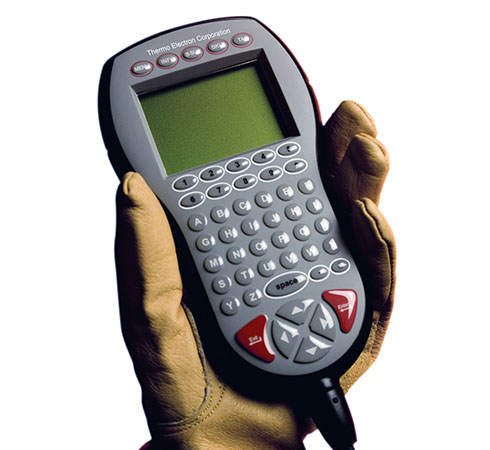

Through a user-centered design approach, Eclipse developed a system that significantly enhanced usability in real-world environments. A fully functional keypad simplified data entry and navigation, streamlining the workflow for professionals operating in high-pressure situations. The addition of a comfortable and ergonomic carry system ensured ease of transport during extended field operations, improving overall user experience and productivity.

The TVA DataManager not only met technical and regulatory performance benchmarks but also increased customer satisfaction and operational efficiency—making it a standout solution for professionals in environmental monitoring, industrial hygiene, and hazardous material response.

Eclipse began the project with a comprehensive research phase, working closely with Thermo Electron to deeply understand the needs, challenges, and workflows of end users in the field. This user-focused approach extended beyond just product development—it helped shape a new, holistic perspective on how Thermo could support their clients’ entire workflow, from deployment to data collection and reporting.

Through field observations, stakeholder interviews, and task analysis, Eclipse identified key opportunities to improve usability, portability, and efficiency. These insights informed the creation of a fully ruggedized and integrated systemdesigned specifically for the demanding conditions of field testing. Notable innovations included a 360-degree visible feedback ring for immediate status indication from any angle, and a modular backpack system that improved mobility and user comfort in dynamic environments.

The project’s accelerated timeline—moving from research through design and development to launch in under 12 months—demonstrated a highly collaborative and focused effort. The final product not only launched successfully but has since exceeded expectations, delivering measurable improvements in workflow efficiency, user satisfaction, and operational reliability.

The new toxic vapor analyzer features a modular backpack system engineered for maximum comfort and usability in the field. Designed with integrated cable management and dedicated holsters for both the display and probe, the system ensures that all components are secure, organized, and easily accessible. Color-coded quick-release clips simplify setup and teardown, enabling fast, intuitive attachment of corresponding parts—even while wearing gloves.

To improve reach and usability, the display and input controls were separated from the probe, transforming the probe into a lightweight, wand-like tool ideal for accessing tight or obstructed areas. Adding a 360-degree LED feedback ring to the probe allowed users to visually detect vapor threshold breaches from any angle—instantly and without distraction—only alerting when emissions exceed safety limits.

This thoughtful integration of ergonomic design and real-time feedback delivers a streamlined, field-ready solution that improves both comfort and confidence during toxic vapor detection tasks.